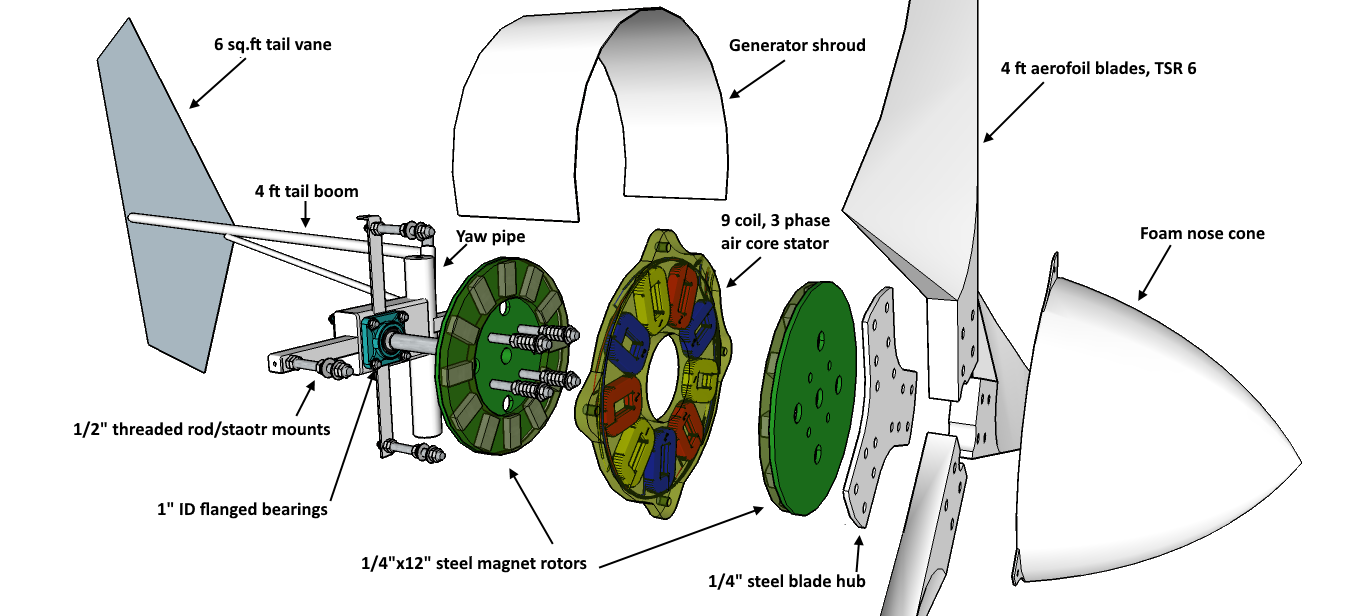

how to build a 1 kw wind turbine

Axial flux off grid wind turbines are among the most efficient micro turbines currently available. They're also a simple design that's relatively easy for any backyard builder to produce completely from scratch with basic tools and skills, and for an affordable cost. The build article below explains how with detailed step by step instructions. Dimensional drawings and a 3D model for this project are available for download here.

introduction

An axial flux generator is configured so that the magnet flux (field) runs parallel to the rotor shaft. The stator is commonly referred to as an ‘air core’ stator because it contains no steel to cause a cogging effect. Cogging is a pulsating resistance that's inherent in some radial flux designs that's caused by the steel cores that the stator coils are wound around. Cheap and underpowered Ebay and Amazon turbines are notorious for it. The steel helps carry the flux from the magnets across a relatively large air gap through the coils. This increases the power output from a radial design. Unfortunately, as the magnets on the rotor pass the coils, they become attracted to the steel cores and naturally want to 'lock' in position over them if this isn't compensated for in the design. It's physically and audibly noticeable as the turbine vibrates and hums while the rotor is turning. This resistance can be strong or weak depending on the design, but either way it requires more wind power to overcome. This translates to a higher startup wind speed requirement, which means lower operation time and a lag in response time between gusts, and thus less kWh's produced at the end of the day which makes for a less efficient turbine compared to an air core axial flux generator that isn't slowed by an added resistance like cogging.

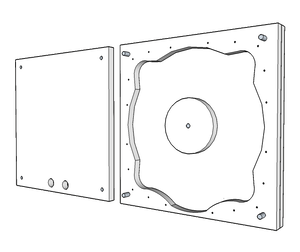

In an axial flux generator, the coils are encased in a fiberglass reinforced resin and the subsequent stator assembly is mounted between two large, round steel rotor plates to which neodymium magnets are attached on the inside faces with alternating poles facing the stator. The steel rotor plates move in unison and direct the magnet flux from the poles on one plate, across a thin air gap through the coils to the poles on the other plate and back without causing a cogging effect. A toddler could literally turn the blades with one finger under load, whereas some radial flux designs require a monkey wrench to turn by hand. This is a significant difference that shouldn't be overlooked, whether building or buying a wind turbine. Not all radial flux turbines are like this. Some will perform just as good as an axial flux, but it is an issue that builders and consumers should be aware of.

In an axial flux generator, the coils are encased in a fiberglass reinforced resin and the subsequent stator assembly is mounted between two large, round steel rotor plates to which neodymium magnets are attached on the inside faces with alternating poles facing the stator. The steel rotor plates move in unison and direct the magnet flux from the poles on one plate, across a thin air gap through the coils to the poles on the other plate and back without causing a cogging effect. A toddler could literally turn the blades with one finger under load, whereas some radial flux designs require a monkey wrench to turn by hand. This is a significant difference that shouldn't be overlooked, whether building or buying a wind turbine. Not all radial flux turbines are like this. Some will perform just as good as an axial flux, but it is an issue that builders and consumers should be aware of.

Turbine Specs

Rotor diameter: 8 ft (2.4 m)

Swept area: 50 sq.ft (4.65 sq.m)

Blades: 3 at 48” (1.2 m), TSR 7

Generator: 3 phase dual rotor axial flux

Power: 1000 watts

Rated wind speed: 25 mph (48 km/h)

Cut-in rotational speed: ~180 rpm

Swept area: 50 sq.ft (4.65 sq.m)

Blades: 3 at 48” (1.2 m), TSR 7

Generator: 3 phase dual rotor axial flux

Power: 1000 watts

Rated wind speed: 25 mph (48 km/h)

Cut-in rotational speed: ~180 rpm

tools needed

Measuring tape, pencil

Square, straight edge & protractor

Centre punch (for metal)

Hammer

Wire brush

1” wood chisel

Coarse flat and round files

Three or four bar clamps

Small weight scale

Hand saw

Jigsaw

Palm sander w/ 80-200 grit sandpaper

Table saw or circular saw

Mini-grinder w/ cutting and grinding wheels

Welder (mig or arc)

Power drill w/ ⅛”-½” metal drill bits, & 1”-1 1/4" hole saws

Digital multi-meter

Soldering iron

Square, straight edge & protractor

Centre punch (for metal)

Hammer

Wire brush

1” wood chisel

Coarse flat and round files

Three or four bar clamps

Small weight scale

Hand saw

Jigsaw

Palm sander w/ 80-200 grit sandpaper

Table saw or circular saw

Mini-grinder w/ cutting and grinding wheels

Welder (mig or arc)

Power drill w/ ⅛”-½” metal drill bits, & 1”-1 1/4" hole saws

Digital multi-meter

Soldering iron

parts & materials needed

One piece of 1-½”x12”, and one piece of 2”x12” schedule 80 steel pipe

One piece of 1”x8’ schedule 40 steel pipe

One piece of 1”x12” steel round bar

One piece of 1"x12" keyed stainless steel TPS shaft

Three 1"ID keyed shaft hubs with 3 or 4 bolt flange

One piece of 2”x4”x6” rectangular steel tubing

One piece of 1”x1”x24” steel angle

Three pieces of ¼”x12”x12” steel plate

One piece of 1”x1/8”x4’ steel flat bar

Two pieces of ½”x4’ threaded rod w/ 70 hex nuts, lock washers and flat washers.

Four pieces of 5/16”x2” hex bolts w/nuts, flat washers and lock washers

One 5/16”x4” hex bolt w/nuts and lock washers

Five pieces of ¼”x 3” hex bolts w/ wing nuts and flat washers

Two 1” ID flanged bearings

One piece of 4’x4’x1” polystyrene

One piece of 4’x4’x5/8” melamine

One piece of ¼”x4’x4’ plywood

One piece of ½”x24”x24” plywood

Twenty one pieces of 2”x4”x4’ clear (knot free) kiln dried cedar

Large bottle of outdoor wood glue

Four cans of primer spray

Six cans of satin white enamel spray

Two liters of casting resin

Twelve square feet of fiberglass mesh or cloth

One large can of Bondo w/hardener

Seven pounds of 14 awg enameled copper wire

Four feet of insulated fine strand 14 awg wire

Twenty four 1”x2”x1/2” N52 grade neodymium magnets

JB Weld kit

Rosin core solder

80-200 grit sandpaper

Small bottle of acetone

30A 3 wire slip ring

3 phase bridge rectifier

One piece of 1”x8’ schedule 40 steel pipe

One piece of 1”x12” steel round bar

One piece of 1"x12" keyed stainless steel TPS shaft

Three 1"ID keyed shaft hubs with 3 or 4 bolt flange

One piece of 2”x4”x6” rectangular steel tubing

One piece of 1”x1”x24” steel angle

Three pieces of ¼”x12”x12” steel plate

One piece of 1”x1/8”x4’ steel flat bar

Two pieces of ½”x4’ threaded rod w/ 70 hex nuts, lock washers and flat washers.

Four pieces of 5/16”x2” hex bolts w/nuts, flat washers and lock washers

One 5/16”x4” hex bolt w/nuts and lock washers

Five pieces of ¼”x 3” hex bolts w/ wing nuts and flat washers

Two 1” ID flanged bearings

One piece of 4’x4’x1” polystyrene

One piece of 4’x4’x5/8” melamine

One piece of ¼”x4’x4’ plywood

One piece of ½”x24”x24” plywood

Twenty one pieces of 2”x4”x4’ clear (knot free) kiln dried cedar

Large bottle of outdoor wood glue

Four cans of primer spray

Six cans of satin white enamel spray

Two liters of casting resin

Twelve square feet of fiberglass mesh or cloth

One large can of Bondo w/hardener

Seven pounds of 14 awg enameled copper wire

Four feet of insulated fine strand 14 awg wire

Twenty four 1”x2”x1/2” N52 grade neodymium magnets

JB Weld kit

Rosin core solder

80-200 grit sandpaper

Small bottle of acetone

30A 3 wire slip ring

3 phase bridge rectifier

suppliers

Neodymium magnets:

https://www.magnet4sale.com/neodymium-magnets/bar-magnets/?sort=featured&page=8

Enameled copper wire:

https://www.remingtonindustries.com/magnet-wire/magnet-wire-200c-14-awg-polyamideimide-7-spool-sizes/

Flanged rotor shaft bearings:

https://www.ebay.ca/itm/303120839538?

Keyed steel shafting & other steel materials:

https://www.metalsdepot.com

Casting resin:

https://www.ebay.ca/itm/133607277231?

Fiberglass:

https://www.ebay.ca/itm/323039855631?

Slip ring:

https://www.hurricanewindpower.com/wind-generator-slip-ring-3-wire-30-amp-per-conductor-wire/

3 phase bridge rectifier:

https://www.ebay.ca/itm/202599319324?

https://www.magnet4sale.com/neodymium-magnets/bar-magnets/?sort=featured&page=8

Enameled copper wire:

https://www.remingtonindustries.com/magnet-wire/magnet-wire-200c-14-awg-polyamideimide-7-spool-sizes/

Flanged rotor shaft bearings:

https://www.ebay.ca/itm/303120839538?

Keyed steel shafting & other steel materials:

https://www.metalsdepot.com

Casting resin:

https://www.ebay.ca/itm/133607277231?

Fiberglass:

https://www.ebay.ca/itm/323039855631?

Slip ring:

https://www.hurricanewindpower.com/wind-generator-slip-ring-3-wire-30-amp-per-conductor-wire/

3 phase bridge rectifier:

https://www.ebay.ca/itm/202599319324?

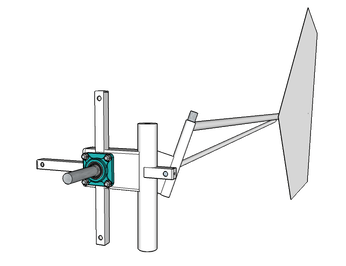

building the frame

step 1

Cut the rectangular frame tubing to length and notch one end to marry with the pipe as shown below. The tubing will be the main frame for mounting the turbine rotor, and the pipe will be the yaw bearing that the turbine will pivot around to track the wind. Tack weld the pieces together, but don't weld them completely. It's best to just tack everything together until all of the components are fitted correctly so that changes are easier to make if needed.

Once they're tacked together, drill a 1 1/4" hole through the widest faces of the rectangular tubing at the locations noted in the plans for the 1" rotor shaft to pass through. The rotor shaft is offset from the center of the yaw at a specific distance as part of the furling mechanism - more on that later. For now, center a flange bearing over the holes and mark the bolt hole locations, then drill them out. Then cap the top end of the yaw pipe with steel plate and drill a 1" hole into it to receive a slip ring later.

step 2

Cut four pieces of steel angle to the lengths indicated in the plans, then notch and fold over a 1" tab on one end of each piece. Weld these steel angles to the rectangular tubing as shown. These will serve as the mounts for the stator and stator shroud. Mark and drill the bolt holes accordingly.

step 3

Cut a right angled triangle from steel plate according to the dimensions in the plans, then tack weld it to the back of the yaw pipe at a 145° angle to the rotor plane. Then weld a 1" steel round bar to the back edge of the steel plate. The bar will be the pivot bar for the furling tail hinge (mechanism). The steel plate holds the bar at a specific compound angle which is dependent on the turbine's size and is necessary for the furling mechanism to work properly at the desired wind speed.

The furling tail hinge works with gravity and wind power to provide an effective overspeed control in high winds (usually >30 mph, 48 km/h). When the wind speed reaches a certain level, the rotor being off-centered from the yaw will cause it to turn out of the wind. The angled furling tail hinge will allow the tail to remain tracking the wind but lifts it in the air during the furling process. With the rotor turned out of the wind, there's less force pushing the blades so they won't exceed a safe operating rpm. As the wind speed decreases to a safer level, gravity overcomes the wind and lowers the tail but remains tracking while the hinge forces the rotor back into the wind to optimize production again.

step 4

Cut and assemble the pipe for the tail boom, then notch the end of the pipe that will slip over the pivot bar for the hinge. Do this in small increments, and test fit each time to make sure that the tail vane isn't going to swing into the path of the blades at full furl, and rests in the proper position relative to the rotor plane when not furled. Then thread the end of the pivot bar to fit a castle nut or drill a 1/8" hole through it just above the top of the tail boom to receive a cotter pin.

Cut a tail vane from plywood and fit it to the tail boom. This is where you can get creative and do something fun and unique, but keep in mind that regardless what you choose for a design, the vane needs to have a specific amount of surface area and weight to track the wind effectively and for the furling mechanism to work at the right wind speed. Use the dimensions in the plans for reference. Once the vane has been fitted, disassemble and clean all of the parts. Then prime and paint.

Cut a tail vane from plywood and fit it to the tail boom. This is where you can get creative and do something fun and unique, but keep in mind that regardless what you choose for a design, the vane needs to have a specific amount of surface area and weight to track the wind effectively and for the furling mechanism to work at the right wind speed. Use the dimensions in the plans for reference. Once the vane has been fitted, disassemble and clean all of the parts. Then prime and paint.

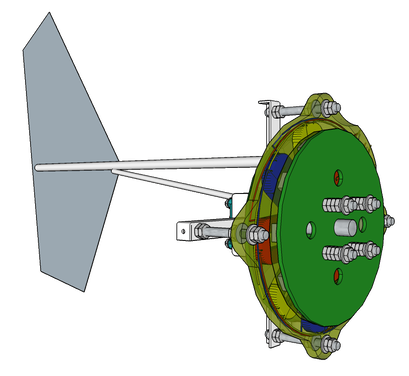

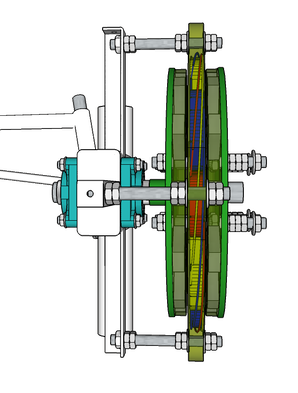

BUILDING THE generator

step 5

Build a makeshift circle cutting jig out of plywood as shown below. It should have a bottom that's large enough to spin a 12" square steel plate on top of it without the corners hitting, and one side with a lever pinned to it with a bolt or dowel. Use pipe straps or heavy duty zip ties to secure an angle grinder (with a cutting wheel) to the lever.

step 6

Drill a 1/4" hole into the center of a 12"x12"x1/4" steel plate and fasten it to the bottom of the jig with a screw at exactly 6" across from the face of the cutting disc on the angle grinder to the center of the steel plate. Set the screw taught; just tight enough to hold the plate flat but loose enough to allow it to spin on the jig without much effort. Then turn on the grinder and gradually lower it onto the plate as you spin it by hand at ~5-10 rpm. Don't put too much force on the grinder. Just focus on spinning the plate and let the cutting wheel do the work. Within 5-10 minutes you should be through the plate and have a perfectly round circle to use for a magnet rotor in the generator. Mark and drill the cooling ports and mounting bolt holes indicated in the plans, as well as the center hole for the shaft to go through. You'll need two of these rotor plates cut and drilled, one of them will need to have the bolt holes threaded for 1/2" bolts. In order for the flux to be directed properly, the plates MUST be a ferrous material like steel. Aluminum will not work. It's important that these plates be as flat as possible, too. Check the material with a straightedge and choose the flattest stock you can find.

Install the flange bearings onto the turbine frame, then cut the stainless steel keyed rotor shaft to length and secure it with the set screws in the flange bearings. Place a rotor plate and keyed shaft hub onto the rotor shaft and mark the bolt holes for attaching the hub to the plate, then drill and bolt them together.

Once the hubs are attached to the rotor plates, rough the inside faces of the plates up with a piece of sand paper (where the magnets will attach) then wipe them clean with a rag and rubbing alcohol. Then place them on a workbench that's free of metal objects and prep to install the magnets.

WARNING!!!

Magnets are typically sold attached together in large blocks and each separated by a thin plastic strip to make removing each mag from the block easier. Because the magnets are so strong (70-80 lbs of pulling power each), you do not want them to come into contact with each other because they will be very, very hard to separate with your fingers and impossible to separate with tools without damaging. When you take a magnet off the block, you should slide it off instead of trying to pull it off, and hold it firmly in a closed hand. If you open your hand and swing it too close to another magnet or metal object, the magnet will jump out of your hand and probably damage itself in the process. Obviously, you'll want to be careful for your own safety as well. Once the magnets are on the rotor plates, they'll have enough force to crush both of your hands like soft fruit. Be very, very careful when working with them.

WARNING!!!

Magnets are typically sold attached together in large blocks and each separated by a thin plastic strip to make removing each mag from the block easier. Because the magnets are so strong (70-80 lbs of pulling power each), you do not want them to come into contact with each other because they will be very, very hard to separate with your fingers and impossible to separate with tools without damaging. When you take a magnet off the block, you should slide it off instead of trying to pull it off, and hold it firmly in a closed hand. If you open your hand and swing it too close to another magnet or metal object, the magnet will jump out of your hand and probably damage itself in the process. Obviously, you'll want to be careful for your own safety as well. Once the magnets are on the rotor plates, they'll have enough force to crush both of your hands like soft fruit. Be very, very careful when working with them.

Step 7

Layout the magnet locations around the perimeter of the rotors using a protractor and marker or pencil. There will be 12 magnets on each plate, which means they will need to be spaced 360° / 12 = 30° apart and rest ~1/8" from the edge of the plate. Once the layout is done, mix up some JB Weld epoxy on a scrap piece of wood and place a small amount on one of the magnet locations. Carefully remove a magnet from the block, place one of the large flat faces against the edge of the rotor plate and slowly roll it into position. Don't drop it into place or you'll risk breaking it. Work the magnet back and forth while applying downward pressure to make sure the entire face adheres to the epoxy. To make placement easier, you can cut a jig out of plywood and fasten it over the rotor plate as a template. This will ensure the magnets end up exactly where they need to be and will help hold them in position to prevent adjacent magnets from connecting with each other while you're working and the epoxy cures.

After the first magnet is set, grab another and while holding it firmly in your closed hand, hold your hand over the magnet you just set into place and determine which side of the one you're holding repels the other and which attracts it. Part of the equation for getting the generator to work properly is alternating the poles that face the stator. opposites attract, which helps make the flux flow. For example, if the magnet you just placed has the north pole facing up, then the two magnets on either side of it will need to have their north poles facing down. Then the magnets beside those should have the north facing up again, and so on as shown below. So if your hand holding the magnet is repelled when you hover it over the one you just placed, then that means the two faces have the same poles facing each other, ie: north is facing north, and you will need to place that next magnet with it's north facing the plate the same way it's resting in your hand. It doesn't matter if you start with a north or a south pole, all that matters is alternating the poles from magnet to magnet around the perimeter. When you've determined which face is which, fasten that magnet in position as you did the first and repeat until all of the magnets are on the first plate.

The second plate will need to have the poles opposite to the first so that when they're bolted up in the generator and facing each other with the stator between, there will be a north pole on one rotor facing a south pole on the other. So, with the plates separated a good distance to prevent accidents, in the same way that you determined the alternating poles between the first two magnets on the first plate, you will need to clasp the very first magnet for the second rotor in your hand and test the poles against the first magnet that you put on the first rotor and make sure that magnet is glued into position on the second rotor plate with the opposite pole facing up - make sure you start at the same location on both plates to ensure they line up in the right position when bolted together. Use a center punch to make a small mark in the plates above or below the starter magnets so they can be identified and lined up during assembly later and you'll know for sure that you'll have alternating poles facing each other.

step 8

Neodymium magnets are highly susceptible to corrosion if the thin nickel plating protecting them is scratched and exposed to moisture. The best way to protect them is to encapsulate them in resin. After the JB Weld has been given sufficient time to cure, the magnet rotors can be prepped for casting.

Cut two 7” diameter circles out of a piece of ½” plywood, then tape the edges. Fasten them directly in the center of the magnet rotors on a flat, level surface. Place tape around the perimeter of each rotor (must be at least ¾” wide). This will serve as the mold for the resin casting, so be sure to use a tape that’s rigid and smooth. Aluminum foil tape works the best. Once the rotors are prepped, mix up ~1L of casting resin and carefully fill both molds until the resin reaches the tops of the magnets. Cut four pieces of fiberglass cloth in the shape of the magnet rotors and place two over each cast. Dab and work the cloth into the resin. Add more resin (if needed) so that it just covers the top of the magnets by <1/16". Let it cure.

Cut two 7” diameter circles out of a piece of ½” plywood, then tape the edges. Fasten them directly in the center of the magnet rotors on a flat, level surface. Place tape around the perimeter of each rotor (must be at least ¾” wide). This will serve as the mold for the resin casting, so be sure to use a tape that’s rigid and smooth. Aluminum foil tape works the best. Once the rotors are prepped, mix up ~1L of casting resin and carefully fill both molds until the resin reaches the tops of the magnets. Cut four pieces of fiberglass cloth in the shape of the magnet rotors and place two over each cast. Dab and work the cloth into the resin. Add more resin (if needed) so that it just covers the top of the magnets by <1/16". Let it cure.

step 9

The heart of the generator is the stator, which consists of a series of enameled copper wire coils. The coils are made using a coil winder, which is a simple plywood jig with a specific mold shape that you will need to make before you can wind the coils. The inner mold of the winder needs to be the same size and shape as your magnets for the best performance. Refer to the plans for dimensions.

Once your jig is made, fasten the wire spool to your workbench with a clamp and small stick, dowel or bar so that it will turn and release wire as you wind the coils. DON’T unwind the spool and then wind the coils, the more twists and turns in the wire before you wind, the messy your coil will end up being. Also keep in mind that the wire has an insulating enamel coating which prevents the windings from shorting out on each other when the generator is running, so take care that this coating doesn’t get damaged.

To make sure the coils that you'll wind will fit in the space required in the stator, you should layout the stator configuration onto a workbench or small sheet of plywood. There will be 9 coils, so they'll need to be spaced 360 / 9 = 40° apart. The center of the coils will also need to line up with the magnets on the rotor plates, so use a compass to draw a circle on the layout that represents the outside perimeter of the magnet rotors, and set the top of the inner diameter of the coils 1/8" below this line so that they line up with the top of the magnets that should be set 1/8" back from the outside edge of the magnet rotors. Then wind a coil and place it at each coil location on the layout, and trace it's perimeter to see if the coils run into each other or not. If they don't, then copy that coil. If they do, then you'll need to either make the coils tighter or resize the magnet rotors - it's easier to wind a tighter coil. If you wind them tight enough, they will fit. But you will need to determine how tight the windings need to be with the first coil before winding them all, or risk wasting all of your copper on loose coils that don't fit. You won't be able to unwind a coil and rewind it tighter, the wire will be too distorted.

To make sure the coils that you'll wind will fit in the space required in the stator, you should layout the stator configuration onto a workbench or small sheet of plywood. There will be 9 coils, so they'll need to be spaced 360 / 9 = 40° apart. The center of the coils will also need to line up with the magnets on the rotor plates, so use a compass to draw a circle on the layout that represents the outside perimeter of the magnet rotors, and set the top of the inner diameter of the coils 1/8" below this line so that they line up with the top of the magnets that should be set 1/8" back from the outside edge of the magnet rotors. Then wind a coil and place it at each coil location on the layout, and trace it's perimeter to see if the coils run into each other or not. If they don't, then copy that coil. If they do, then you'll need to either make the coils tighter or resize the magnet rotors - it's easier to wind a tighter coil. If you wind them tight enough, they will fit. But you will need to determine how tight the windings need to be with the first coil before winding them all, or risk wasting all of your copper on loose coils that don't fit. You won't be able to unwind a coil and rewind it tighter, the wire will be too distorted.

step 10

To start winding the first coil, place the wire against the inner core of the winder and leave approximately 8” of wire hanging out of the winder - this will be the start lead for your coil which will connect to the finish end of the next coil in the phase when the stator is wired up. Carefully turn the coil winder and begin winding the wire around the core. Keep each turn tight against the previous turn so that your coil will have the smallest end dimensions when you’re finished winding and will take up the least amount of space in the stator as possible. These coils will be fit very close together so the more ‘wiggle’ room you can gain the better. Keep track of how many turns you make; every coil should have the same # of turns to increase efficiency and limit waste, but don't get too concerned if you're off by a couple of turns. The generator will still work fine.

For 12V systems you'll need 40 turns of parallel strands per coil, meaning that you will need to wind two wires together so that there are two start ends and two finish ends in each coil that you can twist together to effectively form one large wire. The two wires are needed to increase the current carrying capacity (ampacity) of the coils with thin wire that's easy to form instead of using a single thicker wire like 10-12 awg which would be much more difficult to wind into tight, uniform coils by hand. For 24V systems, you'll need 50 turns of parallel strands per coil, and for 48V systems you'll need 100 turns of single strand wire per coil.

When you’ve reached the required number of turns, leave an extra 8” of wire outside of the winder, then slide a piece of electrical tape through the slot in the winder and wrap each side of the coil to hold it together before you cut the wire and remove the coil from the jig. Don’t try to do this after because the coil will expand as soon as you take the winder apart. When you wind the next coil, do it exactly the same as the first. Consistency pays. You'll need 9 coils altogether.

For 12V systems you'll need 40 turns of parallel strands per coil, meaning that you will need to wind two wires together so that there are two start ends and two finish ends in each coil that you can twist together to effectively form one large wire. The two wires are needed to increase the current carrying capacity (ampacity) of the coils with thin wire that's easy to form instead of using a single thicker wire like 10-12 awg which would be much more difficult to wind into tight, uniform coils by hand. For 24V systems, you'll need 50 turns of parallel strands per coil, and for 48V systems you'll need 100 turns of single strand wire per coil.

When you’ve reached the required number of turns, leave an extra 8” of wire outside of the winder, then slide a piece of electrical tape through the slot in the winder and wrap each side of the coil to hold it together before you cut the wire and remove the coil from the jig. Don’t try to do this after because the coil will expand as soon as you take the winder apart. When you wind the next coil, do it exactly the same as the first. Consistency pays. You'll need 9 coils altogether.

Step 11

After the coils are wound and taped, it’s good practice to check the continuity in each coil to make sure current will flow from one end to the other. To do this, set a multi-meter to ohms and connect each lead from the meter to either end of each coil. If you get the same reading from each coil, you're all set. If you fail to get a reading from one of them, then there's a problem like a scratch in the enamel causing a short and you will need to wind a replacement.

If they all check out, lay them out on your template with the start and finish ends all pointing in the same directions. The stator will need to be wired in a 3 phase star configuration. Prepare the start and finish ends of the coils by cutting them to length according to their connections shown in the wiring schematic, then sand an inch or so of the protective enamel off the ends to expose the bare copper. Preheat a soldering iron, then tin the tip with solder. Tinning simply means placing a small amount of solder on an object to lightly coat its surface. The ends of the coils will need to be tinned to prevent cold joints as well, which would increase resistance in the connections and lower the generator's power output dramatically. So be patient and take care to do this process properly.

If they all check out, lay them out on your template with the start and finish ends all pointing in the same directions. The stator will need to be wired in a 3 phase star configuration. Prepare the start and finish ends of the coils by cutting them to length according to their connections shown in the wiring schematic, then sand an inch or so of the protective enamel off the ends to expose the bare copper. Preheat a soldering iron, then tin the tip with solder. Tinning simply means placing a small amount of solder on an object to lightly coat its surface. The ends of the coils will need to be tinned to prevent cold joints as well, which would increase resistance in the connections and lower the generator's power output dramatically. So be patient and take care to do this process properly.

To connect the coils together, the start wire on one coil (the end that you started winding with) connects to the finish wire of the next coil in the same phase (NOT the coil adjacent to it), and then so on with the final 3rd coil. This is repeated for all 3 phases. For a star configuration, the start ends from the first coils in each phase are soldered together, and the finish ends from the last coils in each phase are the 3 phase output wires that go to the rectifier. However, I personally like to avoid soldering the phase start wires together inside the stator where they would be cast in resin, and prefer to let all 6 wires exit the stator so that I have access to all of them for switching between start and delta configurations. But it's not necessary. A star configuration is all anyone really needs. Refer to the wiring schematic for more detail.

Once again, you should check continuity in each phase with a multimeter after the connections are made. If you don't get a reading from one or more of the phases or there's a large difference in resistance between them, then you have a bad connection or too many/few turns in a coil somewhere and need to fix it before casting the stator in the next step. When you've ensured continuity and resistance is fine, secure the coils and wiring together with electrical tape to make it easier to move from the template to the mold you're about to make.

Once again, you should check continuity in each phase with a multimeter after the connections are made. If you don't get a reading from one or more of the phases or there's a large difference in resistance between them, then you have a bad connection or too many/few turns in a coil somewhere and need to fix it before casting the stator in the next step. When you've ensured continuity and resistance is fine, secure the coils and wiring together with electrical tape to make it easier to move from the template to the mold you're about to make.

step 12

To cast the stator, you'll need to make another mold. Refer to the plans for component dimensions. You can make this with plywood, but it would be better to use something with a smoother finish like melamine, HDPE, acrylic or polycarbonate. If wood is used, the end/edge grain should be sanded smooth and taped or sealed with an acrylic sealer. The smoother the finish is, the smoother the cast will be and the easier it will be to demold without damaging something.

After the mold is constructed, apply a mold release agent to it. This will prevent the resin from crosslinking with the mold and permanently adhering the stator inside of it. You can use a commercial release agent, or something that most people will have in their garage like car wax or petroleum jelly. Use a heat gun or hair dryer to remove any streaks or clumps that might result from using wax or petroleum jelly. Then cut four pieces of fiberglass cloth to match the stator profile, and start mixing up the casting resin.

step 13

Pour a small amount of resin into the mold to wet it, then lay two pieces of the cut fiberglass into the mold with it. Remove any bubbles that might have formed by dabbing the cloth with a paint brush. When the cloth is completely wet, pour a bit more resin in to cover it, then place the stator into the mold with the output wires in the right location to exit the mold after the cover is in place. Fill the mold to just below the top and place the remaining fiberglass pieces over the stator. Wet them with a paint brush, then finish filling the mold until the resin is almost ready to pour over the sides. Place the cover over the mold and tighten it down. Keep the end of the mold with the overflow hole slightly elevated and gently tap on the bottom with a hammer to work air bubbles out, but don't stand the mold completely upright. When you're sure you've removed all or as much air as you can, leave the cast to cure the required time.

step 14

After the cast has cured, demold and inspect it for flaws like exposed air bubbles, cracks from overheating during the curing process, etc. Minor defects like air bubbles can be filled with resin or a resin based filler like Bondo or short strand fiberglass filler.

Use a large sheet of paper as a template to place over the front of the turbine frame and mark the locations of the stator bolt holes in the stator mounts, then transfer those marks to the stator (make absolutely sure the template is centered on the stator when transferring the marks) and drill them out. This is where keeping the wiring in the stator as tight as possible before casting it will pay off. If a wire is in the path of a bolt hole that needs to be drilled, then your only option is to resize the stator mounts so that you can relocate the bolt holes.

If the resin or epoxy you've chosen for casting doesn't have UV protection, then it would be a good idea to paint the stator at this point, as well as the magnet rotors.

Use a large sheet of paper as a template to place over the front of the turbine frame and mark the locations of the stator bolt holes in the stator mounts, then transfer those marks to the stator (make absolutely sure the template is centered on the stator when transferring the marks) and drill them out. This is where keeping the wiring in the stator as tight as possible before casting it will pay off. If a wire is in the path of a bolt hole that needs to be drilled, then your only option is to resize the stator mounts so that you can relocate the bolt holes.

If the resin or epoxy you've chosen for casting doesn't have UV protection, then it would be a good idea to paint the stator at this point, as well as the magnet rotors.

step 15

Now you can finally assemble the generator. Cut four pieces of 1/2" threaded rod to length for the stator bolts and fasten them to the stator mounts with hex nuts and lock washers. The rods should be flush with the hex nuts on the back of the mounts with most of their length protruding in front to receive the stator. Cut four more pieces of 1/2" threaded rod and fasten them to the inside magnet rotor plate as shown below, and install the rotor onto the rotor shaft but don't install any keys or tighten any set screws in the hubs yet. The rods are ~6" longer than they need to be and will serve as the jacking bolts for slowly and safely jacking the second rotor plate into position later.

Once the inside rotor is on, install a hex nut and flat washer on each stator mount bolt approximately 3” away from the stator mount, then install the stator. Install another flat washer and a hex nut on each stator mount bolt to hold the stator in place but don’t tighten these yet because you will have to adjust the stator according to the rotors later.

Once the inside rotor is on, install a hex nut and flat washer on each stator mount bolt approximately 3” away from the stator mount, then install the stator. Install another flat washer and a hex nut on each stator mount bolt to hold the stator in place but don’t tighten these yet because you will have to adjust the stator according to the rotors later.

Install a hex nut and lock washer approximately halfway on each magnet rotor ‘jack’ bolt, then VERY CAREFULLY install the second rotor plate onto the jack bolts. MAKE SURE that you line up the punch marks that you made on each rotor plate so that the magnet poles line up properly (ie: alternated N-S-N-S). Once the second rotor plate is on, install two hex nuts on each bolt just in front of the plate and lock them together without locking against the rotor - it needs to remain a little loose so that the jack bolts can spin. Once you’ve locked the hex bolts together, then you can use the outer one to slowly jack the outer rotor plate toward the stator.

The tighter you can squeeze the rotor plates together without rubbing against the stator, the better. This air gap should be as thin as possible for the best performance. Just be careful not to touch the output wires with your bare hands when spinning and checking the air gap, otherwise you'll receive an electrical shock.

When jacking the outer rotor plate, stop approximately 1/4" away from the stator. Adjust the gap between the stator and the back rotor plate and tighten the nuts on the stator mount bolts to lock it into place. Then finish jacking the outer rotor and lock it into position with hex nuts and lock washers. Install the shaft keys for the rotor hubs and tighten the set screws to lock the rotors to the shaft.

The tighter you can squeeze the rotor plates together without rubbing against the stator, the better. This air gap should be as thin as possible for the best performance. Just be careful not to touch the output wires with your bare hands when spinning and checking the air gap, otherwise you'll receive an electrical shock.

When jacking the outer rotor plate, stop approximately 1/4" away from the stator. Adjust the gap between the stator and the back rotor plate and tighten the nuts on the stator mount bolts to lock it into place. Then finish jacking the outer rotor and lock it into position with hex nuts and lock washers. Install the shaft keys for the rotor hubs and tighten the set screws to lock the rotors to the shaft.

step 16

Make the blade hub to the dimensions shown in the plans and install it onto the remainder of the (jacking) mag rotor bolts protruding from the front of the generator. They should still be long enough to connect the blade hub directly to them. Use the blade hub to safely spin the rotors for a quick test.

Wire the start and finish wires of one phase together (assuming that you didn't wire and cast the stator in star configuration and have all 6 wires to work with). Spin the rotor. You should notice a pulsating resistance. If the rotor still spins freely, check that you have the right combination of start and finish wires. You should get this pulse when you check the start and finish wires of each phase. Once you’ve confirmed this, connect ALL of the wires together to short them out. Try to spin the rotor. It should be extremely hard to turn. This will also be the case if you cast your stator in star and connect the three output wires together. Shorting the phases together effectively brakes the turbine, ie: slows the blades to a near stop. This is the most common way to brake a turbine in emergency situations, or for maintenance, etc. - typically accomplished with a remote brake switch that shorts the phases together when activated.

Connect all of the start wires together, then connect them to one lead on a multi-meter and connect the other lead to one of the phase finish wires. Set the multi-meter for volts AC. Spin the rotor at approximately 60 rpm, just count off in

seconds and complete one revolution per second. The multimeter should give a reading anywhere between 4-5 volts. Check each phase to make sure they produce in the same range. If they do, then your stator is good to go. The output voltage can be adjusted by adjusting the air gap between the magnet rotors. If you want less voltage, widen the air gap. If you want more voltage, narrow the gap (if possible, otherwise use stronger magnets).

seconds and complete one revolution per second. The multimeter should give a reading anywhere between 4-5 volts. Check each phase to make sure they produce in the same range. If they do, then your stator is good to go. The output voltage can be adjusted by adjusting the air gap between the magnet rotors. If you want less voltage, widen the air gap. If you want more voltage, narrow the gap (if possible, otherwise use stronger magnets).

Carving the blades

step 17

Wood is an excellent material for micro turbine blades. Even small aircraft still use wooden propellers (see Culver Props). It's light and semi-flexible which increases rotor response time and the torque applied to the generator to make it operate more efficiently over a wider wind speed range, approx 35% more efficient than stiff fiberglass blades, actually. But it's strong and it's a renewable material that's easily recycled compared to composite blades.

But wood rots, right? Well, yes, if it's allowed to. But it's nothing that a good finish like UV stabilized polyurethane or a couple of layers of fiberglass cloth/resin and regular maintenance won't prevent. All turbine blades require regular maintenance, there's no way around it. Particularly on the leading edges, the portion of the blade that cuts through the wind. They're very susceptible to erosion over time from hitting air particles and precipitation, similar to outboard motor props. All blades should be protected with leading edge tape, which will need to be inspected monthly and replaced from time to time to preserve the blade.

With that said, carving your own blades may seem like more (complicated) work than some are willing to tackle, and that's understandable. Carving and general woodworking experience is a must to make this worth your time and effort. Otherwise, it's simpler just to purchase some blades for your new DIY turbine. For those who think they would enjoy carving their own, continue reading.

Most of the moisture that’s left in a piece of wood after it’s kiln dried is contained in the grains, mostly as a thick sap but with some water content as well, depending on the moisture content that the lumber is dried to (framing lumber is dried to 19% moisture content and furniture/cabinet material is typically dried to around 5%). If a piece of lumber is exposed to high temperatures, such as laying in direct sunlight on a hot summer day, then it could pull more moisture from the grains in the wood and as that happens the grains will shrink, which pulls on the surrounding sapwood and can distort it by cupping or twisting. If the wood is exposed to moisture, both the sapwood and the grain will absorb it and expand, causing distortion and a weight imbalance.

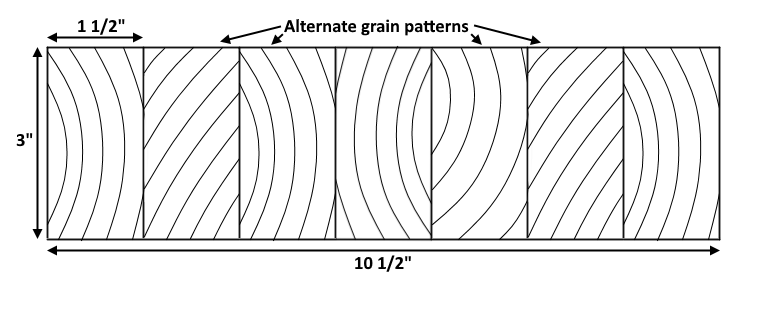

To help lower the risk of deformation if the wood finish fails or is neglected, the blades should be carved from a block of laminated lumber, whereby multiple thinner pieces of lumber are glued with marine grade wood glue and clamped together with their grain orientations opposite to the adjacent pieces, as shown below. This balances any possible shrinkage in the grains across the sum of the pieces so that the lumber will retain it’s original shape. This also helps to increase the blade’s strength for withstanding high wind conditions.

But wood rots, right? Well, yes, if it's allowed to. But it's nothing that a good finish like UV stabilized polyurethane or a couple of layers of fiberglass cloth/resin and regular maintenance won't prevent. All turbine blades require regular maintenance, there's no way around it. Particularly on the leading edges, the portion of the blade that cuts through the wind. They're very susceptible to erosion over time from hitting air particles and precipitation, similar to outboard motor props. All blades should be protected with leading edge tape, which will need to be inspected monthly and replaced from time to time to preserve the blade.

With that said, carving your own blades may seem like more (complicated) work than some are willing to tackle, and that's understandable. Carving and general woodworking experience is a must to make this worth your time and effort. Otherwise, it's simpler just to purchase some blades for your new DIY turbine. For those who think they would enjoy carving their own, continue reading.

Most of the moisture that’s left in a piece of wood after it’s kiln dried is contained in the grains, mostly as a thick sap but with some water content as well, depending on the moisture content that the lumber is dried to (framing lumber is dried to 19% moisture content and furniture/cabinet material is typically dried to around 5%). If a piece of lumber is exposed to high temperatures, such as laying in direct sunlight on a hot summer day, then it could pull more moisture from the grains in the wood and as that happens the grains will shrink, which pulls on the surrounding sapwood and can distort it by cupping or twisting. If the wood is exposed to moisture, both the sapwood and the grain will absorb it and expand, causing distortion and a weight imbalance.

To help lower the risk of deformation if the wood finish fails or is neglected, the blades should be carved from a block of laminated lumber, whereby multiple thinner pieces of lumber are glued with marine grade wood glue and clamped together with their grain orientations opposite to the adjacent pieces, as shown below. This balances any possible shrinkage in the grains across the sum of the pieces so that the lumber will retain it’s original shape. This also helps to increase the blade’s strength for withstanding high wind conditions.

Cut 21 pieces of kiln dried 2”x4” cedar at 48” long, then rip them down to exactly 3” wide. This gives seven 1 ½” thick laminations (2”x4” dressed lumber is actually 1 ½”x3 ½”). Apply glue to the entire 3” face of seven pieces, then clamp them together using bar clamps. If you have enough clamps, repeat this for the other two blades. You can limit the amount of gluing you need to do by rough cutting each lamination to length as seen in the images below. When the glue has fully cured, remove the clamps and scrap off any drips/runs with a wood chisel.

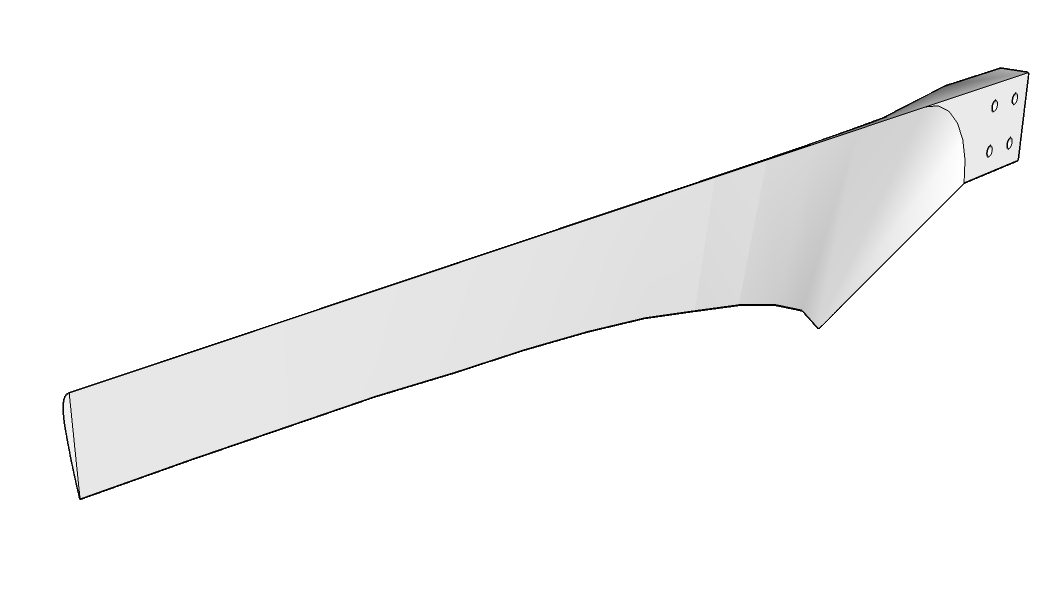

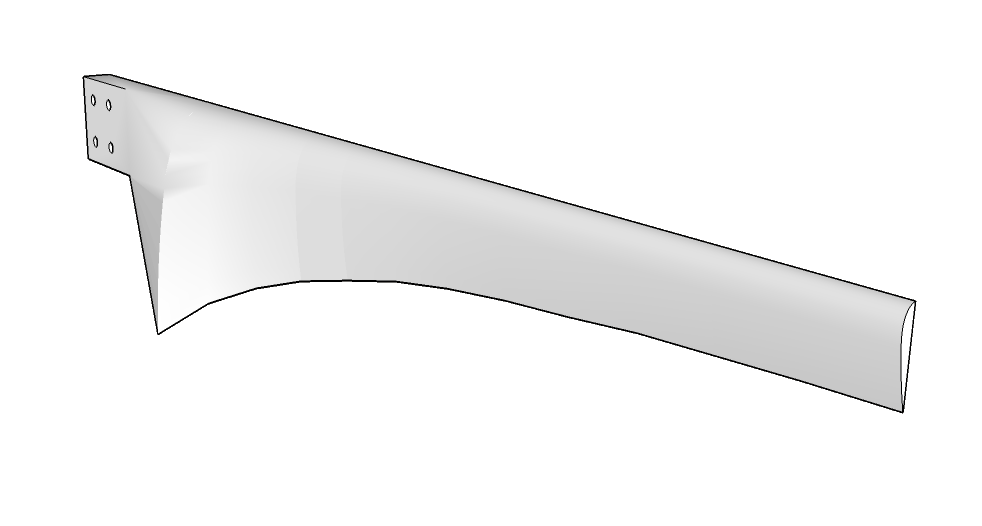

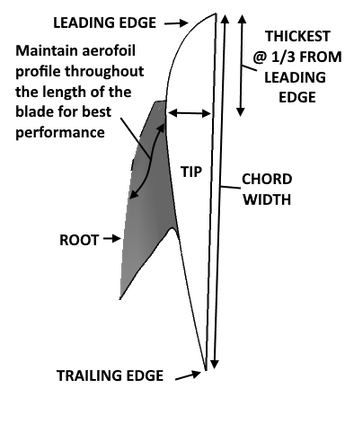

step 18

These blades were designed using blade element momentum theory (BEMT), which means that the length of the blade is equally divided up into elements or stations, and a specific width, thickness and pitch is established at each station depending on the different relative wind angles and forces acting on each station of the blade at a particular wind speed. This produces the washout ‘twist’ that’s necessary for optimizing lift force and overall performance from a horizontal wind turbine. For more information about the physics and mathematics involved in designing these blades and how you can design your own from scratch, visit this link:

https://www.resystech.com/the-diy-wind-turbine-design-guide.html

https://www.resystech.com/the-diy-wind-turbine-design-guide.html

Before carving, you'll need to layout each station of the blade and the necessary parameters onto the lumber stock. These will mainly serve as reference points for removing the bulk of the material. Transfer the layout lines that you see in the drawings below to both faces of your lumber stock (front and back).

These measurements represent the width of the blade at each station, also known as the chord. Remove the

area that you see shaded with a jigsaw - if your blade isn’t long enough you will need to cut from both sides.

area that you see shaded with a jigsaw - if your blade isn’t long enough you will need to cut from both sides.

step 19

From the image below, transfer the layout lines for the blade’s trailing edge to your stock, then carve the front face of the blade. The easiest and most accurate way to do this is to use a handsaw and make saw kerfs approximately every 1-1 ½” along the length of the blade. The bottom of the saw kerf should be straight and connect the front of the leading edge to the layout line that you just drew for the trailing edge. Once the saw kerfs are cut, then simply use a hammer and chisel to knock out the little blocks that were created. Be careful not to break the blocks out below the saw kerfs as this will result in an ugly divot in your blade that will need to be filled.

step 20

Transfer the layout line from the image below to the leading edge of the stock. This line represents the thickness of the blade. The thickness is established at approximately ⅓ of the blade’s width back from the leading edge at each station. This is where the hard curve at the leading edge of the airfoil begins to flatten toward the trailing edge.

Carve the back side in the same way that you carved the front side by making saw kerfs to the required depth at 1” interval along the length of the blade. HOWEVER, the bottom of these cuts have to be parallel to the original rough back face of the lumber stock from station 5 to station 14. From station 2 to station 4, the bottom of the saw kerfs should connect to the leading edge and the trailing edge because the pitch is much steeper closer to the root of the blade - it’s easier to visualize and establish the pitch at the root if you cut station 5-14 first, then carve the finish airfoil

profile using a chisel and/or sharp knife within that range of the blade. Bare in mind that the blade is thickest ⅓ of it’s width back from the leading edge. Transfer the layout line for the ⅓ point representing the thickest part of the blade from the image below to the back of your blade and use it for reference for carving the finish profile.

Once the general shape has been carved, knock down the high spots with a coarse file and repeat these steps for the other two blades

profile using a chisel and/or sharp knife within that range of the blade. Bare in mind that the blade is thickest ⅓ of it’s width back from the leading edge. Transfer the layout line for the ⅓ point representing the thickest part of the blade from the image below to the back of your blade and use it for reference for carving the finish profile.

Once the general shape has been carved, knock down the high spots with a coarse file and repeat these steps for the other two blades

step 21

After you’ve carved all three blades, check their weight with a set of small scales. For the rotor to run smooth and safe, the blade’s weights have to be within a few grams of each other. If you find that one is heavier or lighter than the other two, then balance the blades on a makeshift fulcrum to see which end of the blade is off balance compared to the others, and carefully remove material from the heaviest end with a bastard file or sander until all three blades weigh approximately same. Then touch up the fine sanding, clean, and seal with a finish like acrylic primer and paint, or Minwax Outdoor Spar Urethane (my personal favourite) or you can get even fancier and add some reinforcement with a couple of layers of fiberglass cloth and polyurethane laminating resin.

step 29

Remove the blade hub from the generator and attach the blades using hex bolts, flat washers and lock washers. Before tightening all of the bolts, check the distance from one blade tip to another and verify that the distance is the same between all blades - this will help ensure a proper balance. Then tighten the bolts and install the blade hub onto the rotor shaft.

With the blades installed on the rotor, give them a spin a couple of times to look for an imbalance. If the rotor stops spinning with the same blade pointing down every time, then that will likely be a heavy side and you'll need to add weight to the opposite side of the rotor to counter it. You can do this by adding more hex nuts to the bolts on that side, or fastening lead flashing to the back side of the blade hub or blades. When you spin the blades and they stop at random points each time, then the rotor is as close to balanced as you're going to get it and it's ready to fly. It's important to balance the blades not just for efficiency, but also to prevent wobbles and vibrations that could wear out the bearings prematurely or even cause a complete self destruction in high wind conditions.

Most DIY’ers don’t bother with installing one, but if you choose to then now is the time to make and install a nose cone. This guide won’t go into the details but if you want to see how a fiberglass nose cone is made, visit the link below:

https://www.youtube.com/watch?v=igjUOnZqLvc

Most DIY’ers don’t bother with installing one, but if you choose to then now is the time to make and install a nose cone. This guide won’t go into the details but if you want to see how a fiberglass nose cone is made, visit the link below:

https://www.youtube.com/watch?v=igjUOnZqLvc

installing the wind turbine

This section will just cover general information for installing your turbine, as there are many different methods and applications, and you should thoroughly research what will work best for your needs and apply it. If you need assistance, please feel free to contact me.

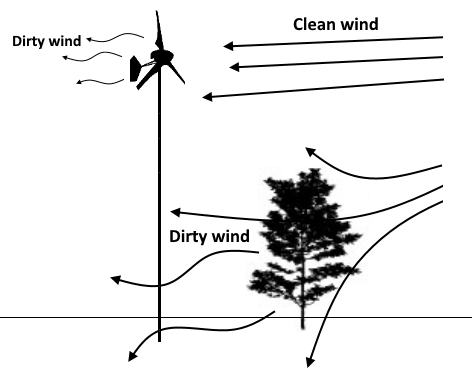

The first thing to do is to decide where to install the wind turbine. A HAWT performs best in clean wind environments where there are no obstacles in the path of the wind to create turbulence and affect the lift force on the blades. It’s strongly recommended that you choose a location where there is at least a 100 foot radius between the turbine tower and any obstacle that could create turbulence, and have your tower high enough that the turbine is above surrounding tree tops and buildings. It’s a good idea to purchase a small hand held anemometer online so that you can physically measure the wind speed periodically in the area to ensure the site receives adequate wind power to justify the installation.

The first thing to do is to decide where to install the wind turbine. A HAWT performs best in clean wind environments where there are no obstacles in the path of the wind to create turbulence and affect the lift force on the blades. It’s strongly recommended that you choose a location where there is at least a 100 foot radius between the turbine tower and any obstacle that could create turbulence, and have your tower high enough that the turbine is above surrounding tree tops and buildings. It’s a good idea to purchase a small hand held anemometer online so that you can physically measure the wind speed periodically in the area to ensure the site receives adequate wind power to justify the installation.

You should also be mindful of neighbours, traffic, building codes, etc. Because the blades can travel much faster than the wind, they can be extremely dangerous if an accident were to happen, such as ice throw from the blades which can cause serious damage to property, injure or even kill a person.

The higher the turbine is, the better it will perform, even in an open field. But you have to know where to set the limit as well because building the tower can be just as if not more costly than the turbine itself. This is part of the reason why choosing the right site is very important. The ROI (return on investment) is the determining factor so weigh the upfront costs with the benefits.

Generally, the best method for constructing a DIY tower is to pour a reinforced 4ftx4ftx4ft concrete slab in the ground to which a pole would be mounted. The pole should have a hinging mechanism with a locking pin about a foot or so above the slab so that the tower can be easily raised or lowered with a winch and a gin pole when needed. The turbine detailed in this guide is designed to fit onto a 1 ½” tower stub, which is a short piece of pipe at the top of the tower. This pipe should be approximately 24” long. The tower pipe should be schedule 80 and at least 2 1/2" diameter. The 1 ½” pipe should be fitted and welded or bolted inside of the tower pipe with approximately 12” protruding from the top for the turbine to mount to. The three phase wires from the generator can then be connected to a slip ring which would fit inside and bolt to the tower stub, or the transmission wires can simply be fed down through the top of the tower pipe to ground level. Contrary to popular belief, a slip ring isn't necessary to keep transmission lines from tangling, as most regions of the world have a dominant wind direction. Meaning the wind usually blows in one direction, and wind turbines rarely make full 360° turns when tracking the wind. It's a good idea to keep an eye on the transmission lines when performing periodic inspections of the turbine and blades, but you'll only need to give the turbine a couple of spins to straighten things out once or twice a year. With that said, a slip ring is relatively cheap and easy to install.

The higher the turbine is, the better it will perform, even in an open field. But you have to know where to set the limit as well because building the tower can be just as if not more costly than the turbine itself. This is part of the reason why choosing the right site is very important. The ROI (return on investment) is the determining factor so weigh the upfront costs with the benefits.

Generally, the best method for constructing a DIY tower is to pour a reinforced 4ftx4ftx4ft concrete slab in the ground to which a pole would be mounted. The pole should have a hinging mechanism with a locking pin about a foot or so above the slab so that the tower can be easily raised or lowered with a winch and a gin pole when needed. The turbine detailed in this guide is designed to fit onto a 1 ½” tower stub, which is a short piece of pipe at the top of the tower. This pipe should be approximately 24” long. The tower pipe should be schedule 80 and at least 2 1/2" diameter. The 1 ½” pipe should be fitted and welded or bolted inside of the tower pipe with approximately 12” protruding from the top for the turbine to mount to. The three phase wires from the generator can then be connected to a slip ring which would fit inside and bolt to the tower stub, or the transmission wires can simply be fed down through the top of the tower pipe to ground level. Contrary to popular belief, a slip ring isn't necessary to keep transmission lines from tangling, as most regions of the world have a dominant wind direction. Meaning the wind usually blows in one direction, and wind turbines rarely make full 360° turns when tracking the wind. It's a good idea to keep an eye on the transmission lines when performing periodic inspections of the turbine and blades, but you'll only need to give the turbine a couple of spins to straighten things out once or twice a year. With that said, a slip ring is relatively cheap and easy to install.

¼” aircraft cable is strongly recommended for using as guy wires to both lift the turbine and support the tower after it’s erected. If the tower is under 20 ft high, then one set of 3 or 4 guy wires around the perimeter of the tower will be sufficient and the turbine can be lifted by hand with two or three people. If the tower is higher then another set of wires will be needed - one set attaches to the middle of the tower and the other set attaches just below the tip of the blades at the top of the tower. The other end of both upper and lower wires would connect together at the same anchor point on the ground. The anchors should also be reinforced concrete slabs in the ground with eye hooks anchored on top to receive turnbuckles - the turnbuckles would be used to tighten the guy wires and level and

secure the tower.

A gin pole and winch or come-alongs should be used to raise a high tower. The gin pole adds the advantage of lifting from a higher plane than from the ground, which helps a lot with first getting a high tower off of the ground. The turbine should never be installed on the tower when it’s first lifted - always do a test lift to make sure things will operate smoothly, and to better establish the cable lengths so that they’re ready to be fastened when the tower is upright but don’t twist or tighten when the tower is being raised or lowered.

The video below shows how a small wind turbine tower is made using a storage shed to raise and anchor the turbine.

secure the tower.

A gin pole and winch or come-alongs should be used to raise a high tower. The gin pole adds the advantage of lifting from a higher plane than from the ground, which helps a lot with first getting a high tower off of the ground. The turbine should never be installed on the tower when it’s first lifted - always do a test lift to make sure things will operate smoothly, and to better establish the cable lengths so that they’re ready to be fastened when the tower is upright but don’t twist or tighten when the tower is being raised or lowered.

The video below shows how a small wind turbine tower is made using a storage shed to raise and anchor the turbine.

battery hookup & grid tie

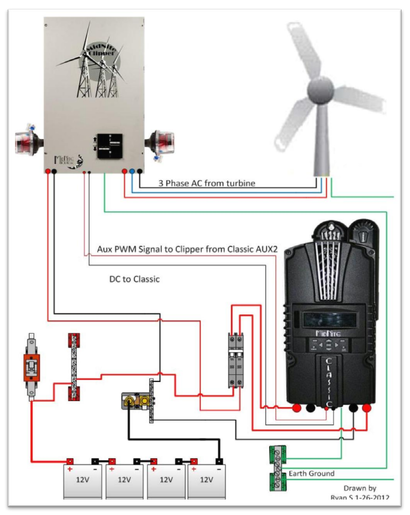

This turbine can be connected to either a battery (bank) or an appropriately sized grid-tie inverter designed to handle wind power. If you want to feed power into the main grid and get paid for it, you will need to set up a net metering account with your local utility. When the boring stuff is settled, you can purchase a grid-tie inverter that

meets local electrical codes, if you don’t already have one. It will need to be able to handle up to 1000 watts of continuous power if you live in an area that regularly gets 30 mph winds or higher. Consult the manufacturer’s specifications and recommendations for installing it.

meets local electrical codes, if you don’t already have one. It will need to be able to handle up to 1000 watts of continuous power if you live in an area that regularly gets 30 mph winds or higher. Consult the manufacturer’s specifications and recommendations for installing it.

If you want to charge batteries, then you will need a diversion (dump) charge controller to do it safely and efficiently. Without a charge controller, a wind turbine can easily overcharge a battery to a dangerous and damaging voltage level if left unattended in windy conditions. A diversion controller measures the battery voltage during charging and when it reaches a certain level, the controller will either cut off power from the turbine to the battery and divert it to a dump load (an electrical load that is equivalent in size to the peak output from the turbine or higher) that will absorb it, or activate a relay to close a circuit between a dump load and the battery bank to feed directly from the battery and lower it’s voltage so that the turbine remains under a load. Either method accomplishes two things: 1 - it maintains a safe

battery voltage, and 2 - it keeps a constant load on the turbine so that it doesn’t free wheel out of control and self destruct. It’s never a good idea to let a HAWT spin freely in the wind without being connected to a battery, grid-tie inverter, or some other electrical load because if the rotor doesn’t spin so fast that it will destroy itself, then the bearings will eventually fail prematurely.

battery voltage, and 2 - it keeps a constant load on the turbine so that it doesn’t free wheel out of control and self destruct. It’s never a good idea to let a HAWT spin freely in the wind without being connected to a battery, grid-tie inverter, or some other electrical load because if the rotor doesn’t spin so fast that it will destroy itself, then the bearings will eventually fail prematurely.

There are two main types of charge controllers commonly used today, pulse width modulation (PWM) controllers and maximum power point tracking (MPPT) controllers. PWM controllers were produced before MPPT controllers and are quite a bit more affordable, but they’re also quite a bit less efficient. The trouble with a PWM controller is that it doesn’t take advantage of the overvoltage produced by a wind turbine. The voltage produced by a wind turbine is proportional to it’s rotational speed (rpm), so the faster the blades spin, the higher the voltage it will produce. If the blades are operating in high winds but the turbine is connected to a PWM, what happens is the turbine rpm is ‘braked’ to within the charging voltage range for the battery bank, and won’t spin any faster and therefor a lot of potential wind power is wasted. If the voltage output is limited, then subsequently overall power in watts will be limited too (volts x amps = watts).

In comparison, an MPPT controller will recognize when the turbine rotor is loading up and wants to spin higher than the charging voltage range for the batteries, and will allow it to do so while converting the excess voltage to amps and taking advantage of the extra power.

Below is a schematic showing how the Midnite Classic controller is wired to a turbine, dump load and batteries. You can read the entire installation manual here.

In comparison, an MPPT controller will recognize when the turbine rotor is loading up and wants to spin higher than the charging voltage range for the batteries, and will allow it to do so while converting the excess voltage to amps and taking advantage of the extra power.

Below is a schematic showing how the Midnite Classic controller is wired to a turbine, dump load and batteries. You can read the entire installation manual here.

Visit the links below to see output from this turbine hooked up to the Midnite Classic MPPT controller:

https://www.youtube.com/watch?v=W4Ajzf4Tysk

https://www.youtube.com/watch?v=X2tUB3XPCGU&feature=youtu.be82

https://www.youtube.com/watch?v=W4Ajzf4Tysk

https://www.youtube.com/watch?v=X2tUB3XPCGU&feature=youtu.be82

using your new wind turbine

Safety should be your #1 priority when using and servicing your wind turbine. Make sure to follow the controller/inverter and battery manufacturer’s recommendations for charge voltage settings, wire/fuse/breaker sizes & placement, disconnect switches, etc. Unless you have experience with wiring such equipment then it’s strongly advised that you allow a licensed electrician to make all of the final hook ups to ensure both safety and the manufacturer’s warranty for the equipment that you didn’t build, and to protect your home.

As mentioned earlier in this guide, a brake switch should also be incorporated into the control circuit so that you can safely brake the turbine for servicing or during dangerously high wind situations. Avoid turning the brake on when the rotor is spinning at high speeds unless it's an emergency, as the torque from a sudden stop can do damage to

the turbine’s components over time. The wind is intermittent so just be patient and wait for it to die down to around 5-10 mph before braking for regular servicing.

It’s a good idea to lower your turbine a day or two after it’s first installed and check the bolts/nuts to make sure they’re still tight, the bearings have lots of grease, the blades are holding up ok, etc. You should also schedule a periodic servicing once every couple of months or so to keep an eye out for fatigue and to grease the bearings,

and keep a log of the maintenance and any signs of progressing issues like blade edge erosion.

As long as your equipment is hooked up properly and scheduled maintenance checkups work out fine, then between that time all you really have to do is relax and enjoy the thought that every time the wind blows above 4 mph, you’re harvesting free, renewable energy.

As mentioned earlier in this guide, a brake switch should also be incorporated into the control circuit so that you can safely brake the turbine for servicing or during dangerously high wind situations. Avoid turning the brake on when the rotor is spinning at high speeds unless it's an emergency, as the torque from a sudden stop can do damage to

the turbine’s components over time. The wind is intermittent so just be patient and wait for it to die down to around 5-10 mph before braking for regular servicing.

It’s a good idea to lower your turbine a day or two after it’s first installed and check the bolts/nuts to make sure they’re still tight, the bearings have lots of grease, the blades are holding up ok, etc. You should also schedule a periodic servicing once every couple of months or so to keep an eye out for fatigue and to grease the bearings,

and keep a log of the maintenance and any signs of progressing issues like blade edge erosion.

As long as your equipment is hooked up properly and scheduled maintenance checkups work out fine, then between that time all you really have to do is relax and enjoy the thought that every time the wind blows above 4 mph, you’re harvesting free, renewable energy.